Production orders in Dynamics NAV allows you to consume both less and more than what’s defined on the components and to output both less and more than what’s defined on the operations in the routing. There is no check when you post, which is nice (sometime I which it was like that on sales and purchase orders as well, but that’s a topic for another post). But when you post more than you wanted you need to be able to reverse it. Luckily reversing production output and consumption is easy if you know how to do it (if the production order has not been finished that is). This blog post describes how to reverse output and consumption on production orders, with and without item tracking.

There are two common scenarios for this (other than someone mistakenly posted more that they should); first one is if you have a process where you issue material against a production order and then return some of it to stock (could be a forward flushing of components for example) and the second one is if you output something that does not meet the expectations (e.g. quality rejects it and it needs to be scrapped). In both those cases you want to do the reversal transactions against the production order to get a correct costing, instead of just doing separate journal entries.

Let’s start with how to reverse consumption.

Reverse Consumption

The trick to reversing consumption is to simply post a consumption with a negative quantity, this will bring the component(s) back into inventory. It can be done in either the consumption or production journal, in the case below we are using the consumption journal where the Order No., Order Line No. and Prod. Order Comp. Line No. are first selected, this brings in the item number and description. After this you enter a negative quantity for what you want to bring back into inventory and make sure the location and bin code are where you want it to end up.

Note the Applies-from Entry, this field can be used to make sure that what goes back into inventory have the same cost as what went out. Not a difference if the component(s) are using the standard costing method, but important if they are using the FIFO or average costing method. What you are selecting in this field is the initial consumption transaction you want to reverse, NAV then links the two transactions and makes sure that if the cost of the initial consumption is changed the corresponding reversal is also changed accordingly.

Posting a negative consumption creates item ledger entries like below. The type is still Consumption, but the quantity is positive and the ledger entry is open.

On a side note; if you have posted multiple consumption and no output and you want to reverse all the consumption then you can use the Calc. Consumption function in the consumption journal and change the Calculation Base On to Actual Output.

NAV will then generate a journal line for each component that’s been consumed with the corresponding quantities being negative (since it is looking at the output which is 0 and suggested what to adjust for the consumption to match this output).

Reverse Consumption with Item Tracking

The next one is to reverse consumption for components that are tracked, in this example we are using a lot tracked component. Entering the journal is done the same as before except that the Applies-from Entry field is not selected.

Then as normal with tracked items you need to go to the item tracking lines to enter the lot number(s). Note that since this is an inbound transaction the lot number needs to be entered manually, then the Applies-from Entry is selected (same way as for the component without item tracking but this time in the item tracking lines page).

Posting the above then creates item ledger entries as below.

Reverse Output

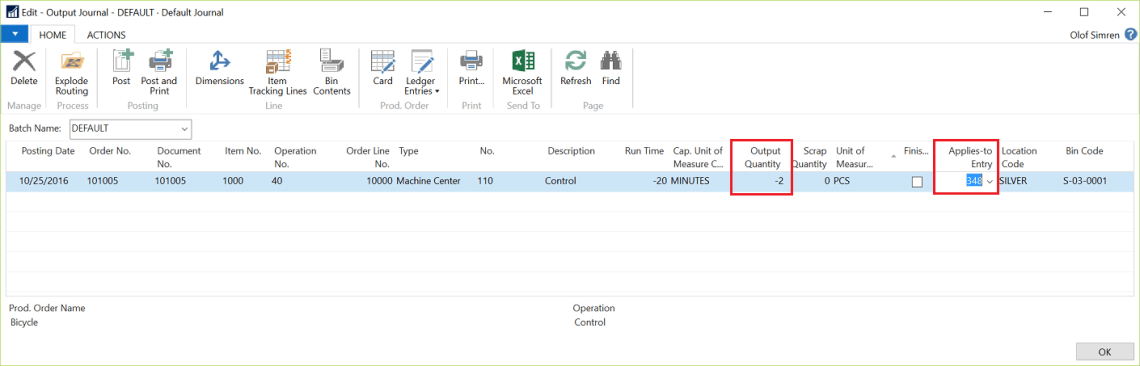

Output can be reversed the same way as consumption; by doing a transaction with a negative quantity. The difference here is that you also have the capacity costs to potentially reverse. Reversing the output can be done in both the production and output journal, in the below case we are using the output journal where the Order No., Item No. and Operation No. are first entered. Then the output quantity is entered as a negative quantity and if you also want to reverse some of the capacity then you can also enter the setup and/or run time as negative numbers.

Note the Applies-to Entry that’s in this case mandatory and it defines what output item ledger entry to reverse. If you are reversing the output for an operation that is not the last one in the routing then you don’t need to enter this value.

If you have the case that some of the output is rejected by quality, then the reversal could be done by entering a negative quantity in the output quantity field and a positive quantity in the scrap quantity field. This way some of the previously posted output is turned into scrap and if you backflush any componants then this is important since you probably want the backflush of the components to be based on the total output including the scrap.

The item ledger entries created when posting the above output journal are as below.

And reversing an output also create capacity ledger entries, the quantity here refers to the time (minutes in this case).

Note that if you want to the setup and run time to default when you enter the output quantity and scrap then this blog post could give you some inspiration; Posting of Actual vs. Expected Production Time.

Reverse Output with Item Tracking

If the item that’s being produced is lot or serial number tracked, then you obviously also need to enter the lot or serial number that’s being reversed. The other difference compared to reversing the output for not tracked items is that you enter the Applies-to Entry in the item tracking pages instead of in the journal. As before this is only required if you are reversing the last operation.

Reverse Output with Subcontracting

This involves doing a purchase credit memo for the vendor, it is a commonly asked questions and I will save this for a separate blog post. Which will be a part 6 in my subcontracting series (the other parts are here if you are interested in subcontracting; Part 1, Part 2, Part 3, Part 4, Part 5).

Reversing a Finished Production Order

This is normally a hot topic, and there is no perfect way of doing it. If a production order has been changed to finished, then you cannot post any more transactions against it. NAV considers it done and have calculated the actual costs and reversed whatever there was in WIP and finalized it from a costing perspective (see production order posting into general ledger for more information). So it is highly recommended that the transactions against a production order are reviewed before finishing it, using the statistics page could help with this.

So, reversing a finished production order typically involves doing journal entries and from a cost and item tracing point of view it will never be perfect (since the costing and traceability in NAV is per production order line and doing something besides this will not affect it). What I have done in the past is a function in the item journal by which a user can select a finished production order and the journal will populate with lines that are as good as you can get from a costing and traceability point of view. This itself deserves a separate post, so stay tuned. 🙂

Remember to share this post if you find it useful.

Discover more from Olof Simren - Microsoft Dynamics NAV & 365 Business Central Blog

Subscribe to get the latest posts sent to your email.

40 Comments

Leave your reply.